Care Label News

Impact of Surface Smoothness and Density on Care Label Printing Effect

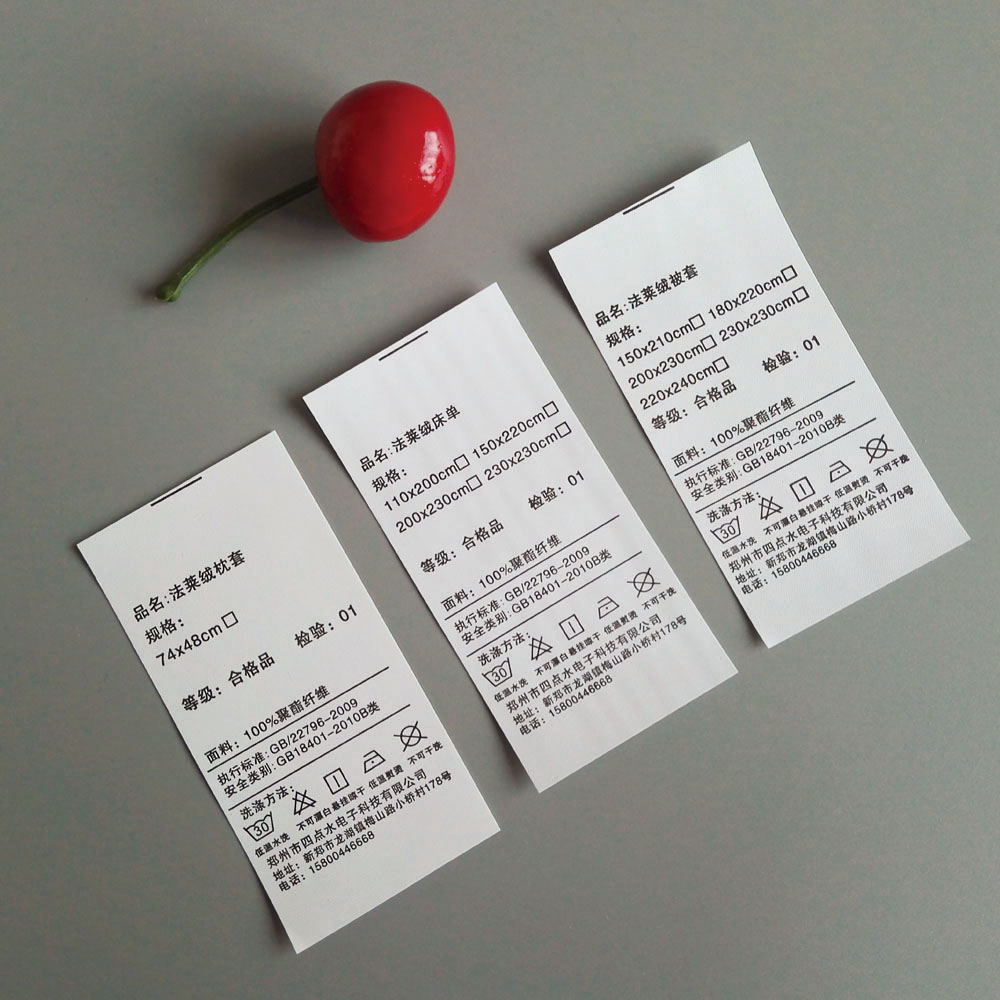

The surface smoothness and density of care label materials significantly influence the quality and clarity of printing. This article explores how these factors determine the printing effect of care labels and considerations for achieving optimal results.

1. Surface Smoothness

Definition: Surface smoothness refers to the evenness and texture of the material's outer layer where printing occurs.

Effect on Printing:

- Print Clarity: A smooth surface facilitates precise ink deposition, resulting in sharp and clear prints of text, symbols, and graphics on care labels.

- Color Saturation: Smooth surfaces allow inks to spread evenly, enhancing color vibrancy and reducing blotching or unevenness in printed images.

- Detail Reproduction: Smooth materials enable the reproduction of fine details and small fonts without distortion or loss of clarity, crucial for legible care instructions and brand logos.

2. Density of Material

Definition: Material density refers to the compactness and thickness of fibers or layers within the care label material.

Effect on Printing:

- Ink Absorption: High-density materials absorb less ink, resulting in sharper and more defined prints with minimal bleeding or feathering.

- Durability: Dense materials offer greater durability, maintaining print integrity and legibility through repeated washing and handling.

- Surface Texture: Materials with consistent density provide a uniform surface texture, contributing to smooth ink application and adherence for lasting print quality.

Considerations for Optimal Printing:

Material Selection:

- Choose care label materials with smooth surfaces and uniform density to optimize print quality and longevity.

- Consider synthetic materials like polyester or nylon for their smooth texture and durability in printing clear and durable care labels.

Printing Techniques:

- Select appropriate printing techniques such as thermal transfer or screen printing, which leverage smooth surfaces and dense materials for precise and durable prints.

- Adjust printing parameters such as ink viscosity and curing temperatures to optimize adhesion and color saturation on different material densities.

Quality Control:

- Conduct print tests and quality inspections to assess how surface smoothness and material density affect printing outcomes.

- Implement regular maintenance of printing equipment and use compatible inks and ribbons to ensure consistent print quality across production batches.

Categories

Latest News

Contact Us

Contact: Peano

Phone: 08618925218435

Tel:

Add: 1st Floor, Building 7, Zhizao Street (Accelerator), Jinwan District, Zhuhai City, Guangdong Province, China