Care Label News

Preventing Static Electricity When Printing Nylon Care Labels in Autumn

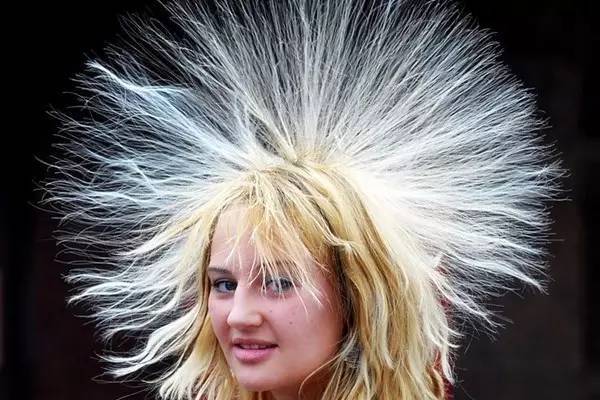

Printing nylon care labels during autumn can be challenging due to low humidity levels, which increase the risk of static electricity. Static electricity can disrupt printing processes and affect print quality. This article explores effective methods to prevent static electricity in printing environments during autumn.

1. Maintain Optimal Humidity Levels

-

Use Humidifiers: Place humidifiers in the printing area to increase moisture levels. Ideally, maintain indoor humidity between 40% to 60% to reduce static buildup on nylon materials.

-

Avoid Over-Humidification: While humidifiers are essential, avoid excessive moisture levels that can cause other issues like mold growth or moisture damage to equipment.

2. Grounding and Antistatic Measures

-

Antistatic Devices: Utilize antistatic bars or ionizers near printing equipment to neutralize static charges on nylon materials. These devices emit ions that counteract static buildup, enhancing print quality and reducing production interruptions.

-

Grounding Equipment: Ensure all printing equipment, including printers and conveyor systems, is properly grounded to dissipate static charges safely.

3. Environmental Control

-

Air Conditioning: Maintain stable indoor temperatures with air conditioning to regulate humidity and temperature levels, creating a more controlled printing environment.

-

Ventilation: Use ventilation systems to circulate air and prevent stagnant air pockets where static electricity can accumulate. Avoid drafts directly impacting printing processes.

4. Handling and Storage Practices

-

Storage Conditions: Store nylon care label materials in a controlled environment with stable temperature and humidity levels before printing to minimize static buildup.

-

Handling Precautions: Ground yourself before handling nylon materials to discharge static electricity. Use antistatic gloves or wrist straps when necessary to prevent transferring static charges.

5. Moisture Control Techniques

-

Water Spraying: Lightly mist nylon materials with water before printing to increase surface moisture temporarily, reducing static electricity during the printing process.

-

Humidity Monitoring: Regularly monitor indoor humidity levels using hygrometers to adjust environmental controls and maintain optimal printing conditions.

Categories

Latest News

Contact Us

Contact: Peano

Phone: 08618925218435

Tel:

Add: 1st Floor, Building 7, Zhizao Street (Accelerator), Jinwan District, Zhuhai City, Guangdong Province, China