Woven Labels

Woven labels with custom shapes and sizes

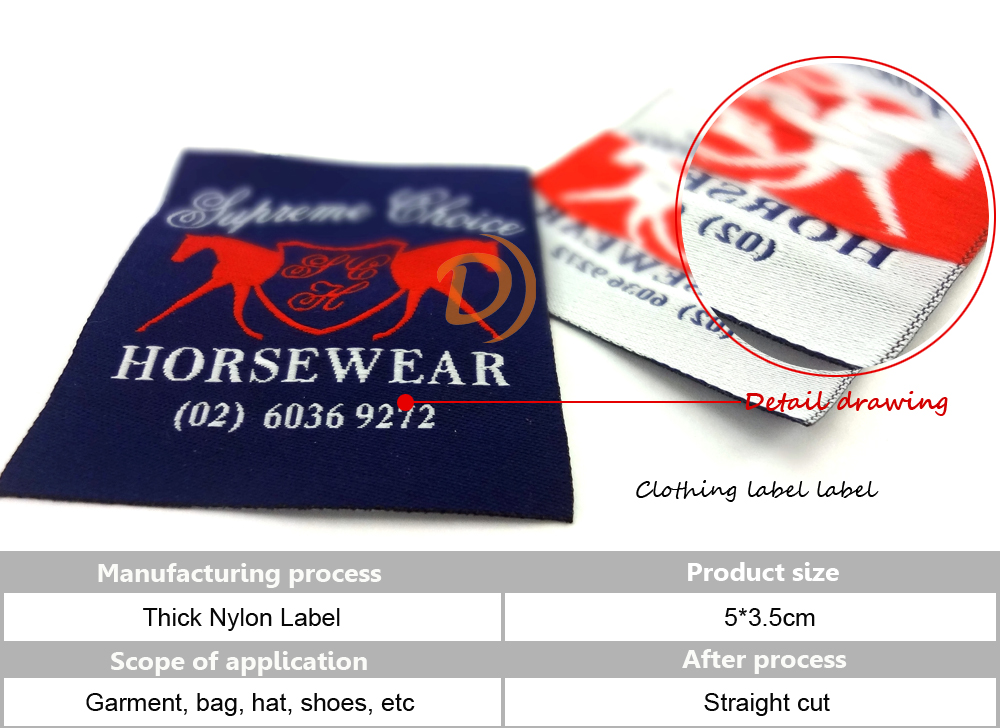

- Product description: Woven labels with custom shapes and sizes offer a unique and versatile way for brands to enhance their products and stand out in the competitive fashion market. By focusing on thoughtful design, high-

Woven labels are a fundamental aspect of garment branding, providing essential information while enhancing the overall aesthetic of clothing and accessories. Moving beyond standard rectangular shapes, custom-shaped and sized woven labels offer brands a unique opportunity to stand out and make a memorable impression. This article explores the benefits, applications, design considerations, and best practices for creating woven labels with custom shapes and sizes.

Benefits of Custom-Shaped and Sized Woven Labels

-

Unique Branding: Custom shapes and sizes allow brands to create labels that are truly unique, helping to differentiate their products from competitors and making them instantly recognizable.

-

Enhanced Aesthetic Appeal: Non-traditional shapes can complement the design of the garment, adding a distinctive visual element that enhances the overall look and feel.

-

Versatility: Custom-shaped labels can be tailored to fit specific design requirements, making them suitable for a wide range of products, from clothing to accessories.

-

Functional Design: Custom sizes can accommodate more detailed information without overcrowding the label, ensuring legibility and clarity.

-

Consumer Engagement: Unique and eye-catching labels can increase consumer interest and engagement, contributing to a stronger brand connection and loyalty.

Applications in Fashion and Accessories

-

Apparel Lines: Custom-shaped woven labels can be used on various types of apparel, such as t-shirts, dresses, jackets, and pants, adding a unique touch to each piece.

-

Accessories: Labels with custom shapes and sizes are perfect for hats, bags, scarves, and other accessories, providing a cohesive and branded look.

-

Children’s Clothing: Fun and playful shapes can make labels more appealing to children and parents, enhancing the attractiveness of kids' clothing lines.

-

Luxury Fashion: High-end brands can use sophisticated custom shapes to convey elegance and exclusivity, reinforcing their premium positioning.

-

Streetwear and Activewear: Custom labels can reflect the edgy and dynamic nature of streetwear and activewear, aligning with the brand’s identity and target audience.

Design Considerations

-

Shape and Size Selection: Choose shapes and sizes that complement the garment’s design and fit well with the overall aesthetic. Consider the practical aspects of label placement and visibility.

-

Material Quality: Select high-quality materials that can be easily cut into custom shapes without fraying or losing integrity. Common materials include polyester, cotton, and satin.

-

Detail and Complexity: Ensure that the custom shape allows for clear and legible display of important information such as brand name, logo, care instructions, and size.

-

Color and Contrast: Use colors that align with the brand’s identity and provide sufficient contrast for readability. Consider how the label will look against different fabrics and colors.

-

Durability: Ensure that the custom-shaped labels are durable and can withstand washing, drying, and regular wear and tear without losing their shape or legibility.

Best Practices

-

Work with Skilled Manufacturers: Partner with experienced label manufacturers who have the expertise and equipment to produce high-quality custom-shaped and sized woven labels.

-

Prototype Testing: Create prototypes and test them on actual garments to ensure they meet design expectations and performance standards.

-

Clear Specifications: Provide detailed specifications to the manufacturer, including shape, size, material, colors, and any special instructions to ensure accurate production.

-

Quality Control: Implement strict quality control measures to ensure each label meets the brand’s standards for appearance, durability, and functionality.

-

Sustainability Considerations: Explore eco-friendly materials and production processes to align with sustainability goals and appeal to environmentally conscious consumers.

Categories

Latest News

Contact Us

Contact: Peano

Phone: 08618925218435

Tel:

Add: 1st Floor, Building 7, Zhizao Street (Accelerator), Jinwan District, Zhuhai City, Guangdong Province, China