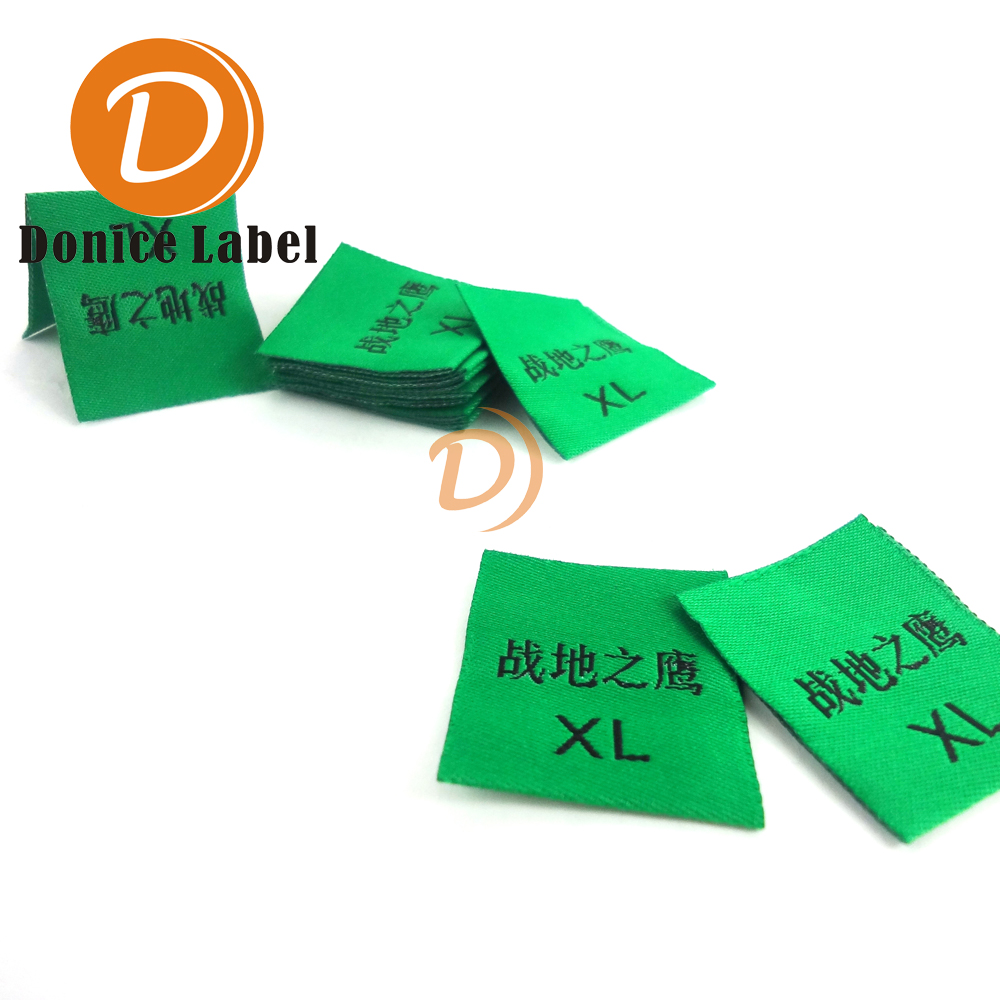

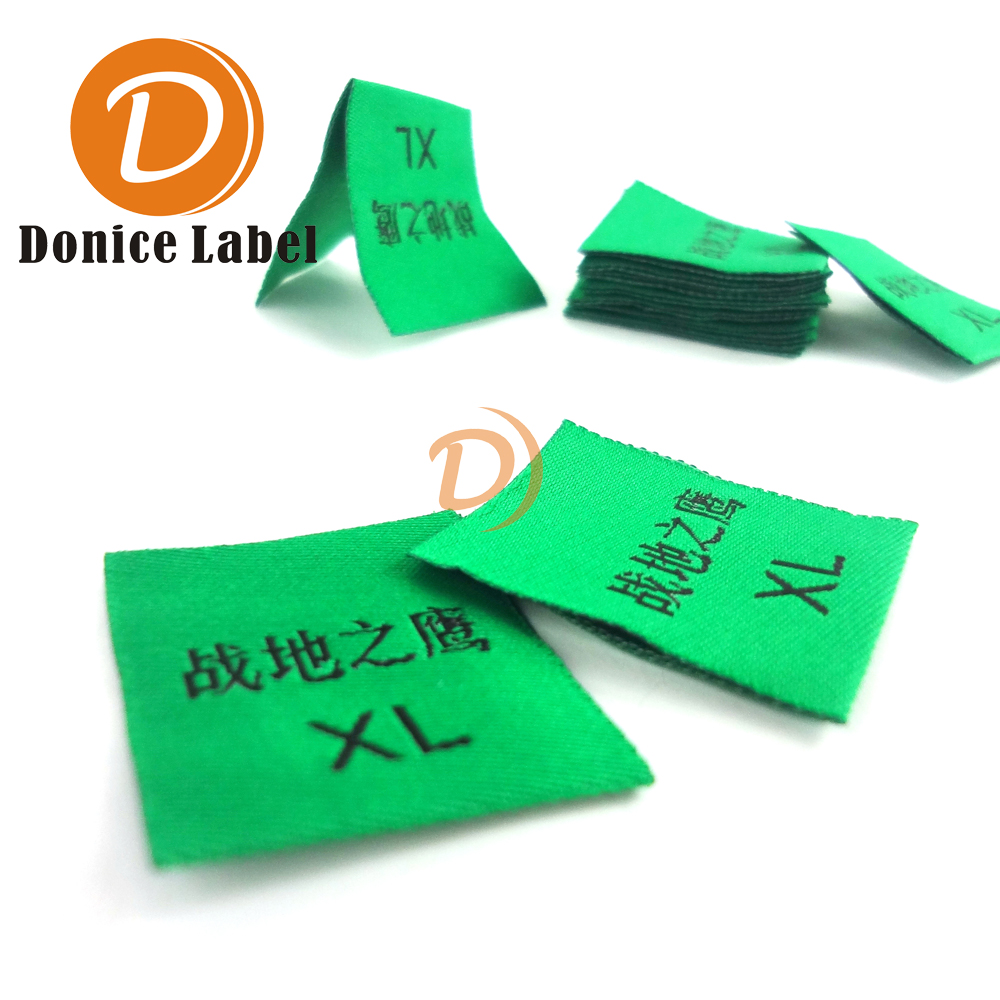

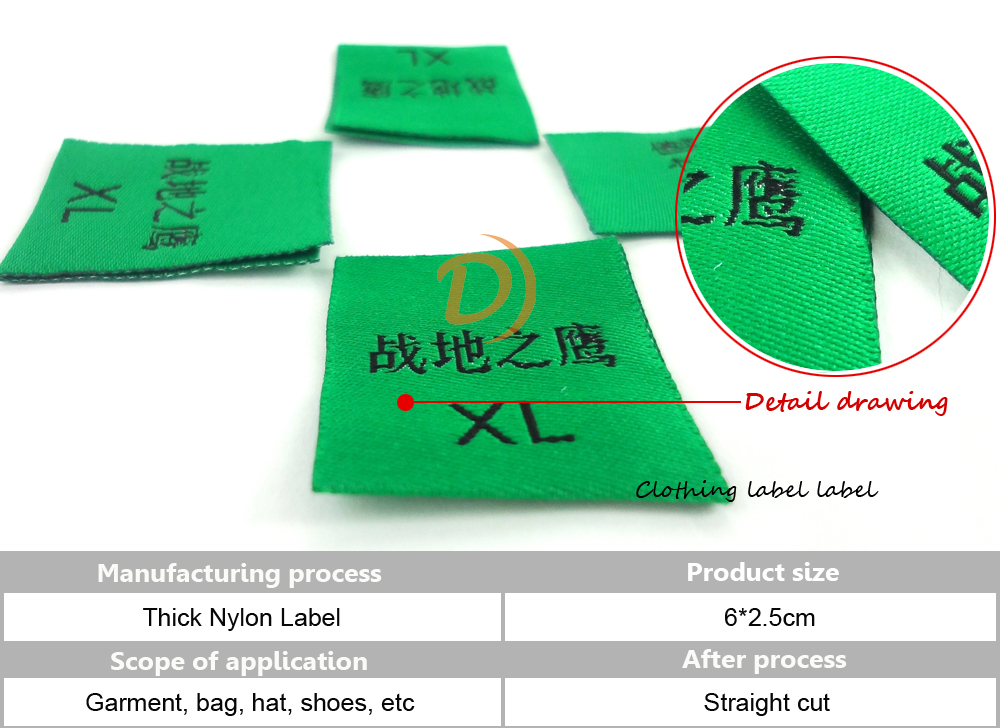

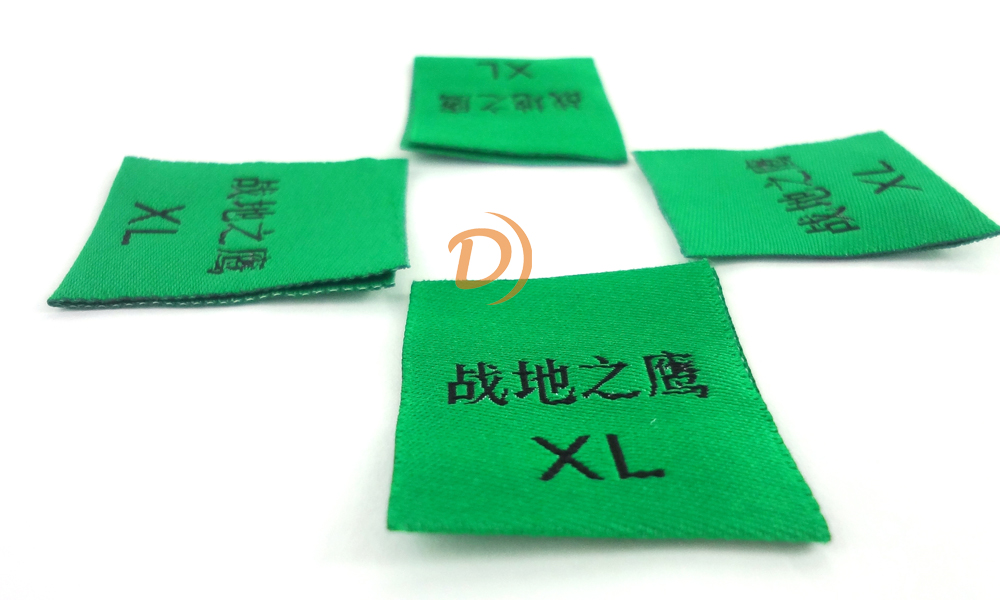

Woven Labels

Custom Woven Labels for Hats and Caps

- Product description: Custom woven labels for hats and caps are a vital component that enhances brand recognition, adds a professional touch, and increases the perceived value of the headwear. By focusing on material compa

Custom Woven Labels for Hats and Caps

Custom woven labels for hats and caps are an essential detail that adds a touch of quality and brand recognition to headwear. These labels not only provide important information but also enhance the overall aesthetic and perceived value of the product. This article explores the benefits, applications, design considerations, and best practices for creating custom woven labels specifically for hats and caps.

Benefits of Custom Woven Labels for Hats and Caps

-

Brand Recognition: Custom woven labels prominently display the brand’s logo and name, helping to increase brand visibility and recognition.

-

Professional Appearance: High-quality woven labels give hats and caps a polished, professional look, making them more appealing to customers.

-

Durability: Woven labels are durable and can withstand the wear and tear that hats and caps often experience, maintaining their appearance over time.

-

Versatility: These labels can be customized to fit various styles and materials of hats and caps, ensuring compatibility with a wide range of designs.

-

Added Value: Including custom woven labels can enhance the perceived value of hats and caps, making them more desirable to consumers.

Applications in Hats and Caps

-

Baseball Caps: Custom woven labels are perfect for baseball caps, providing a space to showcase the brand logo and add a touch of authenticity.

-

Beanies: Woven labels can be attached to the cuff or the top of beanies, offering a stylish and functional branding element.

-

Snapbacks: Snapback hats can feature woven labels on the front, back, or inside, adding to their trendy and casual appeal.

-

Bucket Hats: These versatile hats benefit from woven labels that can be placed on the brim or the side for subtle yet effective branding.

-

Trucker Hats: Custom woven labels can be sewn onto the mesh or front panel of trucker hats, enhancing their rugged and sporty look.

Design Considerations

-

Material Compatibility: Choose materials for the labels that are compatible with the fabric of the hats and caps, ensuring they do not compromise the comfort or fit.

-

Size and Placement: Determine the appropriate size and placement of the labels to ensure they are visible but not obtrusive, complementing the overall design of the headwear.

-

Clear and Legible: Use clear, legible fonts and high-contrast colors to ensure that the brand logo and any other information on the label are easily readable.

-

Durable Stitching: Ensure that the labels are securely stitched onto the hats and caps to withstand regular use and washing.

-

Design Consistency: Maintain design consistency with the rest of the brand’s products, ensuring that the labels align with the overall brand identity.

Best Practices

-

Collaborate with Professionals: Work with experienced label manufacturers who can provide guidance on material selection, design, and production techniques to achieve the best results.

-

Prototype Testing: Develop and test prototypes on actual hats and caps to ensure the labels meet the desired standards for appearance, durability, and comfort.

-

Bulk Production: Plan for bulk production to take advantage of cost savings and ensure consistency across all headwear products.

-

Sustainable Options: Consider using eco-friendly materials and production methods to align with sustainability values and appeal to environmentally conscious consumers.

-

Feedback and Improvement: Gather feedback from customers and use it to refine future designs and improve the overall effectiveness of the woven labels.

Categories

Latest News

Contact Us

Contact: Peano

Phone: 08618925218435

Tel:

Add: 1st Floor, Building 7, Zhizao Street (Accelerator), Jinwan District, Zhuhai City, Guangdong Province, China