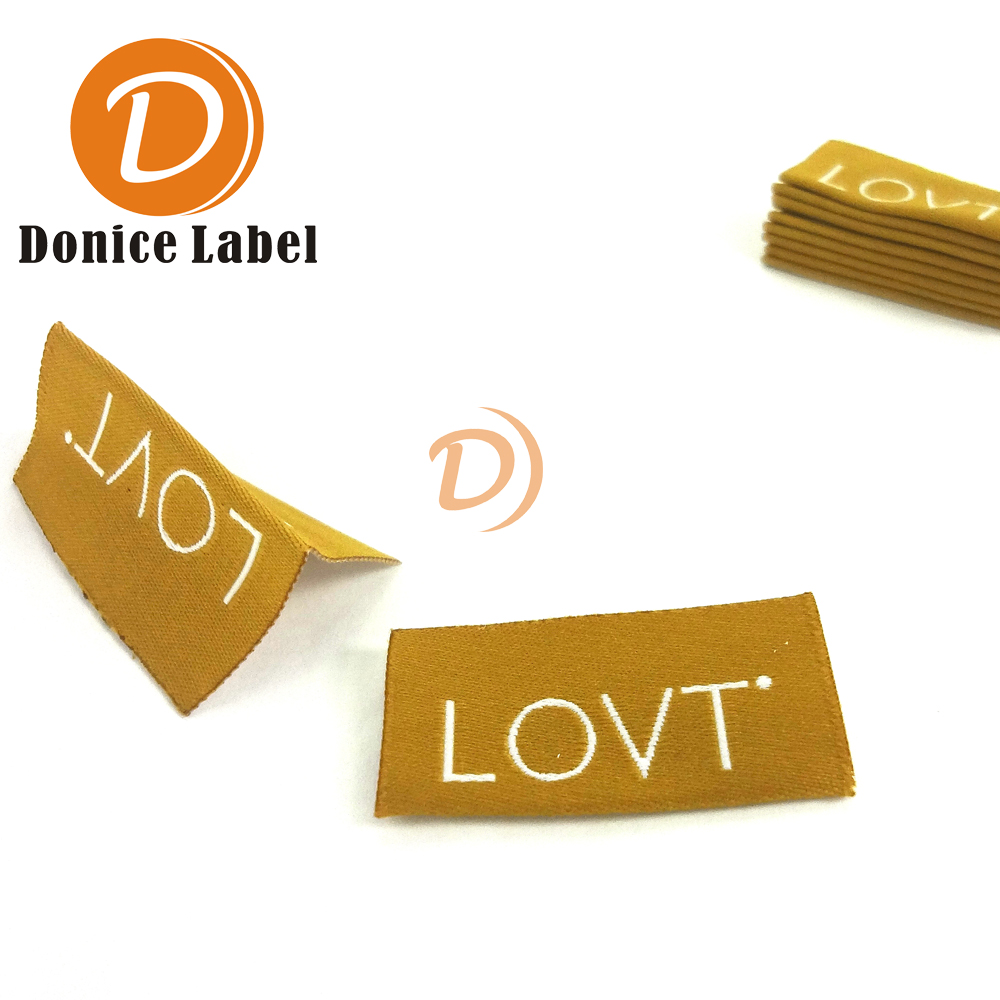

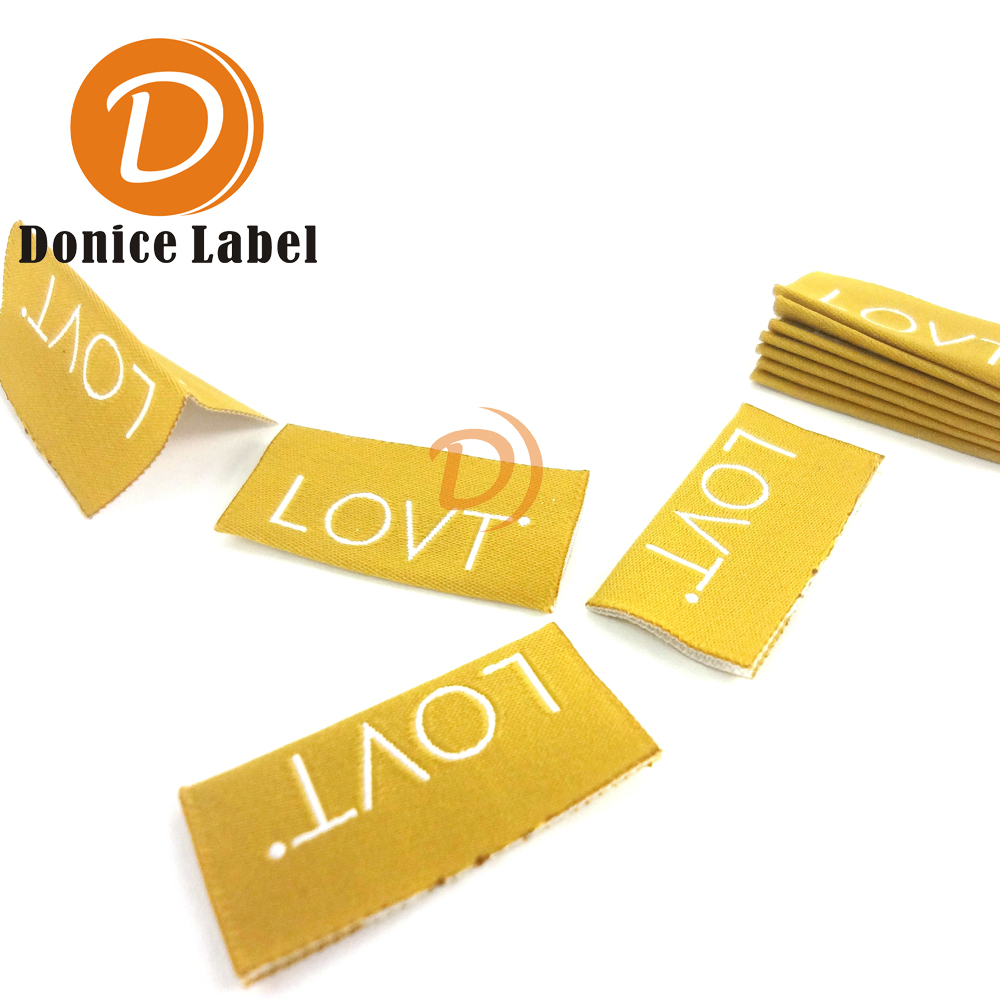

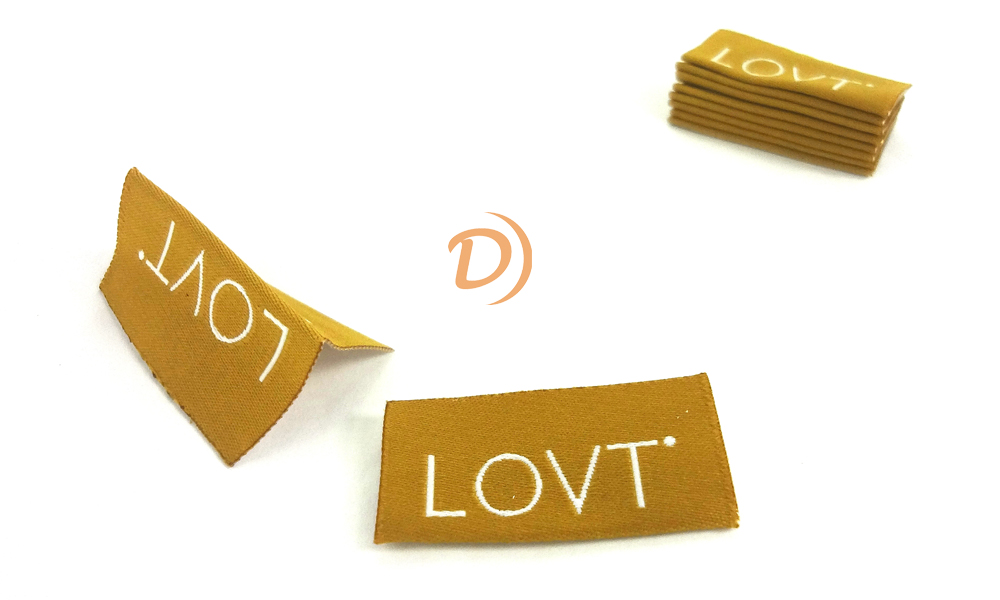

Woven Labels

Durable Woven Labels for Workwear and Uniforms

- Product description: Durable woven labels are a crucial component of workwear and uniforms, providing longevity, brand consistency, and clear information under tough conditions. By focusing on high-quality materials, rein

Durable Woven Labels for Workwear and Uniforms

Workwear and uniforms require labels that can withstand harsh conditions, frequent washing, and heavy use. Durable woven labels provide an ideal solution, ensuring that important information remains legible and the brand identity is consistently represented over time. This article explores the benefits, applications, design considerations, and best practices for creating durable woven labels tailored for workwear and uniforms.

Benefits of Durable Woven Labels for Workwear and Uniforms

-

Longevity: Durable woven labels are designed to last, maintaining their appearance and legibility even after numerous washes and extensive wear.

-

Brand Consistency: These labels help maintain brand consistency across all uniforms and workwear, reinforcing the company’s identity and professionalism.

-

Clear Information: Woven labels provide a clear and reliable way to display essential information such as care instructions, size, and employee identification.

-

Resilience: Made from high-quality materials, durable woven labels resist fraying, fading, and wear, ensuring they stay intact under tough conditions.

-

Professional Appearance: High-quality labels contribute to a polished and professional look, enhancing the overall presentation of workwear and uniforms.

Applications in Workwear and Uniforms

-

Industrial Workwear: Durable woven labels are essential for industrial workwear, such as overalls, coveralls, and protective clothing, where labels must endure rough conditions.

-

Healthcare Uniforms: Labels for healthcare uniforms, including scrubs and lab coats, need to withstand frequent washing and sanitization without losing their quality.

-

Hospitality Uniforms: In the hospitality industry, uniforms for hotel staff, chefs, and waitstaff benefit from durable labels that can endure daily use and cleaning.

-

Corporate Uniforms: Corporate uniforms, such as suits and business attire, require labels that maintain their professional appearance over time.

-

School Uniforms: Labels for school uniforms need to be durable enough to survive the rigors of daily wear and washing, while still looking neat and tidy.

Design Considerations

-

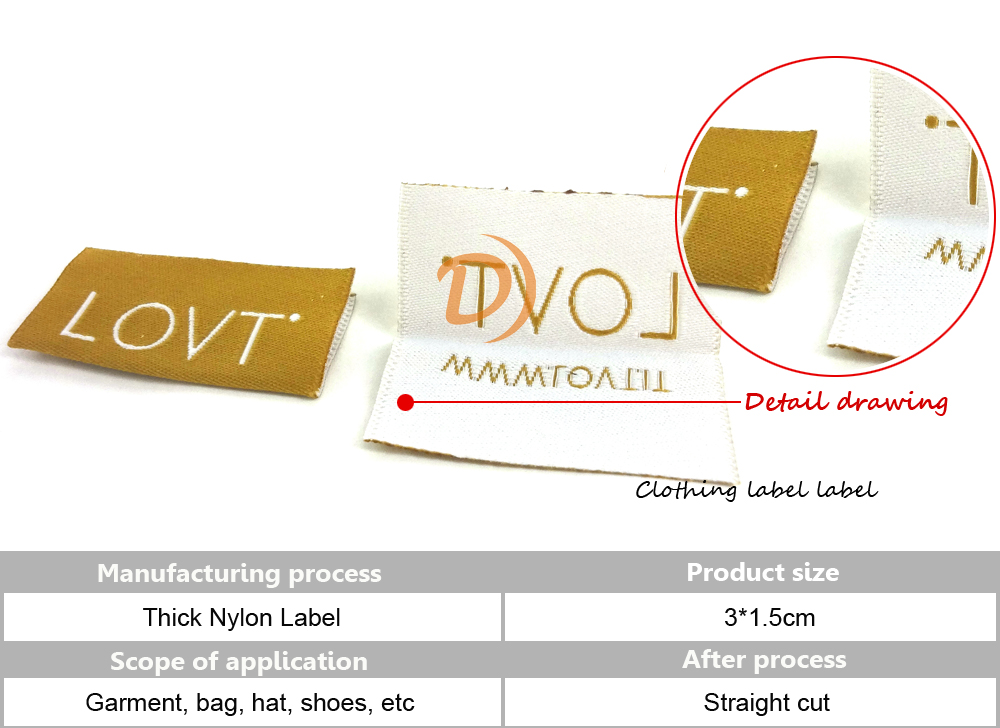

High-Quality Materials: Choose materials that are specifically designed for durability, such as polyester or nylon, to ensure the labels can withstand tough conditions.

-

Reinforced Edges: Opt for labels with reinforced edges to prevent fraying and maintain a clean, professional look.

-

Clear Printing: Use clear, legible fonts and high-contrast colors to ensure that all information on the labels is easily readable.

-

Secure Attachment: Ensure the labels are securely attached to the garment, using stitching or heat-sealing methods that prevent detachment during heavy use.

-

Functional Design: Consider the placement of the labels to ensure they are functional and do not interfere with the comfort or performance of the workwear or uniforms.

Best Practices

-

Work with Experienced Manufacturers: Collaborate with manufacturers who have experience in producing durable woven labels and understand the specific requirements of workwear and uniforms.

-

Rigorous Testing: Conduct rigorous testing of the labels under conditions that simulate real-world use to ensure they meet the desired standards for durability and legibility.

-

Consistent Quality Control: Implement strict quality control measures to ensure that all labels produced are free from defects and meet the required durability standards.

-

Customization Options: Offer customization options for companies to include specific information such as employee names, logos, and barcodes on the labels.

-

Sustainable Practices: Consider using eco-friendly materials and sustainable production methods to align with the growing demand for environmentally responsible workwear.

Categories

Latest News

Contact Us

Contact: Peano

Phone: 08618925218435

Tel:

Add: 1st Floor, Building 7, Zhizao Street (Accelerator), Jinwan District, Zhuhai City, Guangdong Province, China